Explanation: anti-slip glass in walkon rooflights

Walkon glass can be made more slip-resistant using an anti-dirt coating, by sandblasting the glass or with a special ceramic anti-slip pattern ‘frit dot pattern’. We explain the possibilities in detail.

Anti-dirt coating for walkon glass makes glass dry faster

With an anti-dirt coating, water runs off the glass faster. The advantage of this coating is that the glass remains completely transparent. The anti-dirt coating does not provide anti-slip in the sense of making the glass more rigid. So what does the anti-dirt coating do?

In short, it ensures that:

- slippery dirt does not stick;

- glass dries faster.

Dry glass has a PVT value well above the required 36 (enough anti-slip).

But beware: even with an anti-dirt coating, wet glass is not anti-slip.

How does an anti-dirt coating work?

Glass seems slippery, but it is not. When studying it under a microscope, you can see that glass has a coarse surface, due to which dirt, salt and lime can easily attach to it and make the glass dirty. When applying a anti-dirt coating, a protective layer of polymers is fitted to the glass. These will very strongly attach to the glass and also form strong mutual bonds. This does not only make the glass more smooth and easier to clean, but also it makes it stronger.

An advantage of the coating is that it creates a real bond with the glass. This makes it extremely strong and abrasion-resistant, even when it is being walked on.

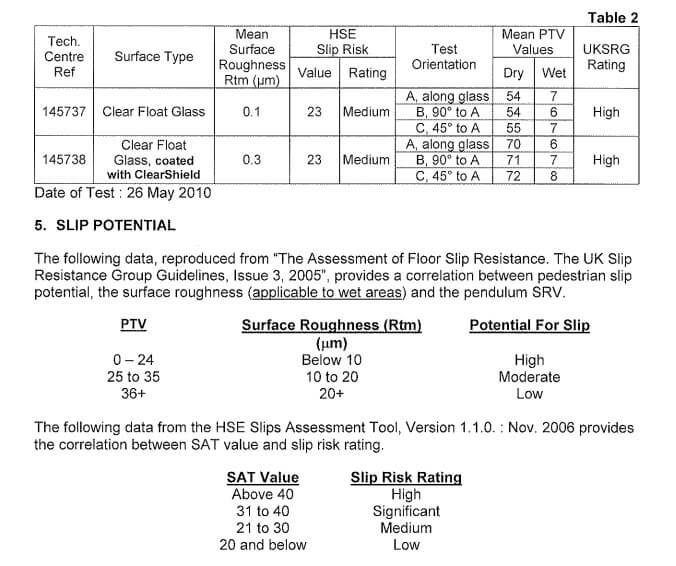

Explanatory note anti-slip values HSE and PTV

A disadvantage of the coating is that it doesn’t ensure better values for more ridged glass. For both untreated glass and glass with the anti-dirt coating, the average value for slipping risk (HSE Slip Risk) is 23 which makes it average.

For dry glass the value of glass treated with anti-dirt coating is better than standard glass, but as long as the glass is wet, there is a high risk of slipping.

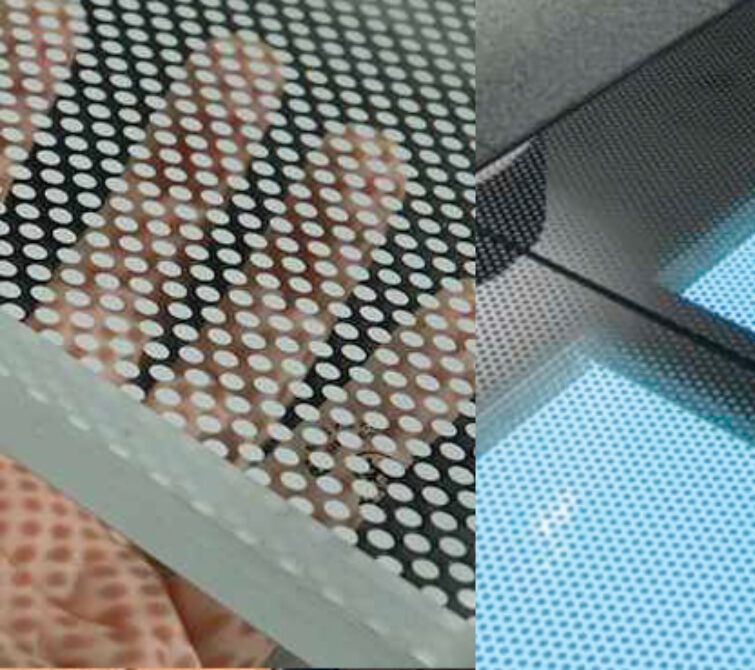

Anti-slip solution: Sandblasted glass

It is also possible to sandblast the glass. This creates an anti-slip factor of 50, somewhat less than the frit dot pattern, but more than enough above the required 36 for properly ridged glass.

This is a relatively cheap solution. What could be a disadvantage of this, is that the glass is no longer transparent. The light yield will however remain almost equal, albeit that the light entry is more diffuse.

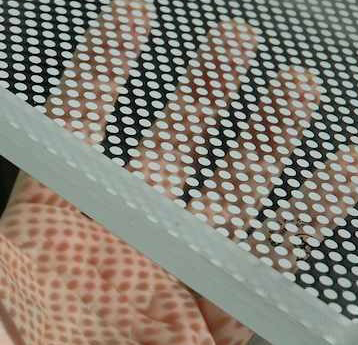

Anti-slip solution: Frit Dot pattern

This involves using a laser to apply dots of 8mm raw material to the glass. This can be done in an even dot pattern, but also, for example, in the shape of a logo. This is a nice, yet very costly method. The clearness will be reduced by some 40% relative to solution no. 1, while the light entry remains the same. The anti-slip value of 60 is the highest of all solutions.

Discover the products in this article

Blog

With endless possibilities, it is helpful to find the right inspiration. Below you can see all our realized and possible solutions in one overview.

View all